The Generator Will Not Start Troubleshooting Overview

Generators, in general, can be lifesavers during emergencies.

They work efficiently to allow a continuation of your businesses when there are extended power outages.

But sometimes, the generator will not start troubleshooting, you can solve some of those by following this post.

As valuable as these machines are, they are not 100% perfect.

Generators can malfunction occasionally. And it is important to understand how to troubleshoot issues on your generator effectively.

Check out Best parts for generator on AmazonGetting this knowledge will assist you to be off the lurch at a time when you are in need of a power backup.

What Can I Use to Clean a Carburetor?

With the twigs grass, and other kinds of debris that engines encounter, the passages in the carburetor may ultimately get affected.

Deposits that accumulate in the carburetor may easily clog air and fuel passages, reducing performance or even stopping the engine.

Fortunately, it is easy to clean up the carburetor easily and quickly, without necessarily removing the carburetor off the engine.

The commercially available carburetor cleaners come in spray cans that are convenient for periodic cleaning of the outside as well as inside parts of the carburetor.

Apart from cleaning the carburetor, most problems of engine performance can easily be linked to issues of maintenance such as dirty air filter, stale fuel, deteriorated oil, and fouled spark plug.

A convenient way to avoid these problems is by performing an annual tune-up.

How Does a Generator Start?

A generator starts by converting mechanical energy which is often obtained externally into electrical energy.

It is good to understand that generators do not actually “create” electrical energy.

Generators utilize mechanical energy which is supplied to it forcing movement of electrical charges that are present in the wire windings it has, via an electric circuit created externally.

The flow of electric charges consists of the output electric current that is supplied by this generator.

How Do You Service a Generator?

> Check the oil level. Look for the dipstick in the oil tank and remove it.

Identify the mark on this dipstick and the oil line, which indicates the level of oil in the tank.

If the oil has reduced, fill the oil up to the dipstick’s indicated mark, but ensure not to overfill.

Follow the recommendation of the manufacturer when changing the oil to avoid any further generator problems.

>You need to use high-quality oil such as the 30-weight detergent for summer conditions, or a 10W-30 for winter conditions, but it is always wise to refer to the oil recommendations in your engine manual.

>Regularly turn on an unused generator – it is one of the easiest preventive maintenance services you can offer your generator.

Running your generator with an occasional load is a good idea, as it prevents the production of gum on the carburetor by a gas.

>Remove Gasoline before Storing the Generator – This is a good thing to do before storing your generator for a long period of time.

This is especially if you plan on storing it indoors. It is recommended not to keep combustible materials indoors.

>You can also change the fuel filter regularly – Just close up the fuel valve, then remove clamps on the sides of the filter, and pull off the old one.

You can then look through the filter in order to ensure you see light through it shining. If you don’t see this, then consider replacing it.

Petrol Generator Won’t Start

* Check the Spark Plug– Do inspections on the spark plug for any signs of damage or wear.

If there is a crack on the porcelain insulator, or the electrode is damaged or burned away, just replace this spark plug.

To determine a defective spark plug, you can use a spark plug test. There should be a strong spark in the terminals of the spark plug tester as the engine is cranking.

If a spark doesn’t appear, it indicates a defective spark plug and should t, therefore,e replaced.

You should also conduct a replacement if there is a heavy carbon buildup at the electrodes.

* Check the carburetor – The carburetor should also be checked for any clogging.

Carburetor clogging is often caused by leaving fuel inside the generator for some time.

Over this time when the generator is not being used, some ingredients in the fuel may evaporate to leave behind a thick and sticky substance.

The sticky fuel can easily make the carburetor clog up and prevent starting of the engine.

If the carburetor happens to be clogged, clean it using a carburetor cleaner.

If cleaning does not show any effectiveness, replace or rebuild the entire carburetor.

* Check the Generator Ignition Coil– The ignition coil usually send voltage to the spark plug during the performance of the engine.

If the ignition coil happens to be defective, the engine may fail to start.

Before doing any replacements of the ignition coil, you need to ensure that the spark plug is working perfectly.

After you have made this confirmation, use an ignition coil tester to test the ignition coil and replace it if it’s defective.

How Do You Start A Generator That That Has Been Sitting?

First of all, perform an oil service which includes checking the fuel and air filters – consult the maintenance manual for service intervals.

Check the fuel feed, change the engine oil, and start the generator to see if it goes well.

There is a need to start worrying about the effects of additives in modern fuels on small engines.

For a level of ethanol above 10%, it can be a problem with your generator.

Is your Generator Having Gas Leaks?

The carburetor’s gasket may be missing or dried out. If the leak is originating from the carburetor’s bottom, replace the gasket of that carburetor.

You also need to check the float bowl gasket of the carburetor at the bottom. In case you detect any leakage, replace the float bowl gasket.

Also, check the bowl gasket of your carburetor at the bottom of the carburetor. If it is missing or dried out, just replace it.

Generator Battery Keeps Dying

Check on the Voltage Regulator – As the generator’s engine run, the voltage regulator should send a proper quantity of voltage to the battery from the alternator, so that the battery can remain charged.

In case the voltage regulator becomes defective, the battery will not receive enough voltage, and this will cause the battery to drain faster.

To test for continuity, use a multimeter to know if the alternator has a fault.

Generator Won’t Keep Running

As fuel gets consumed by the generator engine, the fuel level in the tank lowers.

The fuel cap then uses a small vent for allowing air to enter the fuel tank in order to make up for this lowering.

In case the fuel cap vent becomes clogged, air cannot enter the tank, and a vacuum often referred to as “vapor lock” occurs.

This makes the flow of fuel toward the carburetor to stop, and this causes stalling of the engine.

To determine a clogged fuel cap, slightly loosen the cap and start the engine again. If after loosening the fuel cap makes the engine run, then clogging has happened and replacement at this point is vital.

Generator starting problems on gas

If your generator is giving you some issues, then there are some easy ways to help figure out the problem and find a solution. Here are just a few.

▪︎ Out of gas!

It’s best to use fresh gas, old gas will cause clogging and other issues. Check your gas levels and fill if needed.

▪︎ Check the oil.

Be sure to place your generator on a level of space while using it. This will ensure all levels will be accurate. Check the oil in the crankcase and fill it if it is needed.

▪︎ Choke lever failure.

Check the positioning of the choke lever and make sure it is correctly on Open.

▪︎ The fuel valve is clogged or closed.

Be sure that the valve is in the open position. If the valve is not closed then you need to follow steps to unclog it.

▪︎ The carburetor is clogged.

If you didn’t empty the carburetor and left your generator for periods of time the old gas will clog it. If this happens release the bowl to clean the old fuel.

These are the common 5 gas generator startup issues. Most problems can be fixed with a little elbow grease.

Preventive maintenance is important when preserving the life of your generator.

Generator choke problem

Because the main use of a choke on a generator is to the amount of the flow of air into your engine, sometimes the combination of air and fuel that goes into the cylinder can be out of wack.

Starting The Generator

When starting a cold engine, the choke should be closed — otherwise, there could be problems with enough furl getting into the cylinders to keep the generator engine running.

Engines on a generator need to warm up if they have been cold for long periods of time.

Having too much air by opening the choke can be the root cause of your choke problem due to wear.

Generator Maintenance

It is best to check the oil levels of the generator and making sure that the choke is fully closed if you are having problems with keeping your gas generator going.

Downsides To Using The Choke

Some could argue that there are downsides to using a choke. Here is the shortlist:

• Generators burn more fuel with the choke open;

• Opening the choke while it is running produces more fuel deposits;

• The choke could wear out and need replacing;

• The carburetor could need replacement from continual use.

With a gas generator, it is best to properly maintain your equipment, so there are fewer issues with your choke in the long run.

Troubleshooting Generator Problems

How to troubleshoot: a Generator that Fails to Start

One of the most common causes of this problem is that people would usually let the fuel be stored inside of the generator’s oil storage.

The reason why it is important for you to drain and clear out the fuel from the generator if you decided that you would not be using the generator for such a long period of time is that we would like to prevent the oil from clogging the engine as well as the pump of the fuel which would require you to take the generator to a mechanic in order for you to clear out the clogs.

However, it may also be due to the fact that the fuel in the generator is stale.

If you strongly think that stale fuel is the cause then simply clear out the fuel tank of your generator and refill the fuel tank with fresh fuel.

Apart from that, you should also make sure that the fuel shut off valve of the generator is not engaged.

Generator Running but No Power?

When the power goes out in your house, the first thing most people would tell you to do is check your generator.

If you do that and your generator seems to be working fine, though, what are you supposed to do next?

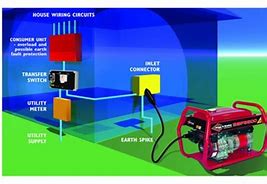

1. Check the Circuit Breaker

The first thing you should do in this situation is to ensure the circuit breaker is working properly.

If it’s not working properly, you will have to replace it. Some signs of a non-functional circuit breaker include:

Burning smell “0” reading on the multi-meterDamage to the breaker

2. Check the Control Box

If the circuit breaker seems to be working fine, the next step is to check your control box.

Much like the breaker, it will probably be obvious if something is wrong with it. Look for physical damage or wires that seem out of place.

3. Ask for Help

If you tried the above tips along with other troubleshooting and nothing seems to work, it might be time to dial up the generator company and ask for assistance and/or a new generator.

How to Troubleshoot When the Generator Will Not Start

The most common reason why your generator does not start is engine flooding. This happens when too much fuel collects in the combustion chamber and then wet fuel deposits on the spark plug. You can check to make sure this does not happen by waiting 5 minutes and checking that all the connections are tight and in the correct position. Once the generator has started, you should also check the choke and the air filter. If you haven’t checked these things yet, they are the most important factors that may be the cause of your problem.

Check the gas in the fuel tank. If the gas level is low, you should siphon some fuel from the tank and fill it up with fresh fuel. If you have to, make sure the old fuel is completely gone. It’s important to run the generator dry to ensure that the engine oil doesn’t dry out. If you can’t siphon the old fuel, try running it dry.

If you don’t have the proper fuel, you can check the oil level in the fuel tank. If the gas is low, the oil level is too low. The ignition coil and the low oil sensor are essential to keep the generator running properly. If the problem persists, you should contact a professional for repair. Then, check the spark plugs and the oil level. Sometimes, a spark plug is damaged or too dirty to light.

More Generator About Troubleshooting Guide

Knowing how to maintain a generator is important in owning one, and having the knowledge on the troubleshot of a generator is an added advantage.

This way, you know how to come up with the proper solution to get your generator running again.

There are instances when a generator just abruptly stops functioning altogether. Your generator may be running when some of these have happened:

Your generator battery keeps malfunctioning your generator’s gas is constantly leaking your generator refuses to start

When the battery keeps malfunctioning, this is usually due to something that went wrong in the voltage regulator (which sends the needed amount of voltage from the alternator to the battery to keep the battery charged.)

When the gas of your generator keeps leaking, one of the possible causes may be due to damage in the fuel tank which is the proximate cause of the leak itself.

When your generator refuses to start, it may be to the carburetor being clogged which may have been caused by leaving the fuel in the generator for too long.

Conclusion

Generator sets – often used for either backup or prime have to be maintained regularly in order to ensure they offer quality power in their entire service life.

Check out Best parts for generator on AmazonLarge companies that operate many generators for prime power may need in-house engineers to maintain their generators.

For smaller companies who own a generator for providing backup power in case of an outage, do establish maintenance contracts with dealers of generators or electrical contractors for maintaining their generators.

In this case, the life-cycle of generators is well documented and established, and ultimately ensuring routine maintenance is fairly straight-forward.

The best maintenance practice of generators is achieved by following the schedule of maintenance recommended by the generators’ manufacturers.

Related articles